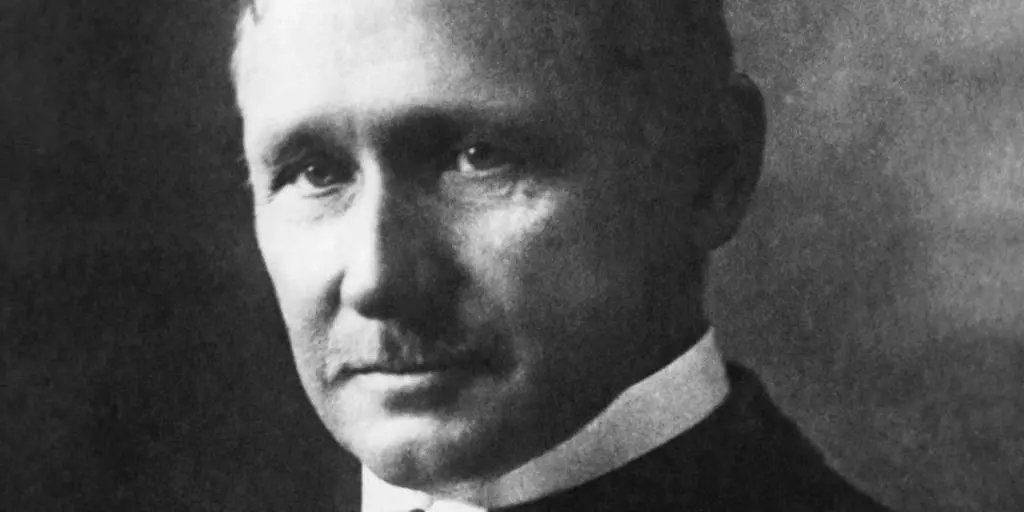

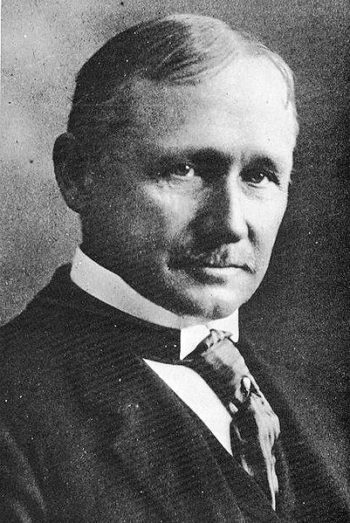

Winslow Frederick Taylor Scientific Management Theory

Winslow Frederick Taylor is one of the founding fathers of modern organizational studies, and his findings have greatly influenced many aspects of our work today. His scientific management approach has undoubtedly touched many aspects of your professional life.

Winslow Frederick Taylor was a mechanical engineer and a management consultant, which meant that he was an outside person who would come into organizations to help them make things better.

Factories at the time are springing up everywhere, and standardized ways didn’t yet exist to manage large groups of people and handle increasingly complex work.

Taylor identified this need and wanted to step in and make organizations more standardized, efficient, and productive by closely studying their work processes.

Scientific management (also known as Taylorism) is the term he used to refer to his management approach. He did a lot of studies and wrote books about it. It means applying science to work, studying tasks carefully, systematically at the micro-level to speed up work. He wanted to break away from the common-sense rules of thumb that he saw his unproven and inefficient.

On June 23rd, 1903, Frederick Winslow Taylor spoke to a room full of people about one of American society’s biggest threats. He was speaking to them about the topic of national efficiency.

Taylor presented that national efficiency was far more significant and argued that the wasted human effort that was mostly unnoticed prevented the country from reaching its optimal productivity level.

Winslow Frederick Taylor Principles of Scientific Management

Features of Scientific Management Theory

In Taylor’s book, The Principles of Scientific Management, he expounded upon these ideas and ultimately provided a blueprint and supporting evidence for implementing what we know to be scientific management.

💥🎁 New Year & Easter Deals On Amazon !

Don't miss out on the best discounts and top-rated products available right now!

🛒 Shop Now and Save Big Today!*As an Amazon Associate, I earn from qualifying purchases.

Taylor believed that every action could be reduced to a science. He claimed that the workers were not operating at anything close to what he called maximum efficiency and that wasted effort was rampant among task-oriented work.

In his studies, he found out that the specific social incentives do not increase their productivity, and workers would engage in what is called soldering, which essentially means that you would work at a deliberately slow pace to avoid the abuse from coworkers who didn’t want management to find out that increasing productivity was possible.

It meant that if one worker begins to show increased productivity, management may begin to require this level of productivity as the new norm.

During this period, workers were commonly paid what was known as a Fair Day’s wage. Management would determine this wage by observing what they believe to be a fair day’s work.

Essentially, all employees should produce and then uniformly pay this wage to all workers, regardless of output.

So you can probably imagine there wasn’t a strong incentive to increased productivity since workers were paid the same day’s wage.

Regardless, if anything, workers under the system had an incentive to engage in soldering so that management wouldn’t expect additional productivity for the same day’s wage. After all, who wants to expend additional energy or work longer hours for the same pay?

Probably not many, and those who did give in to other workers’ peer pressure and reduce their output. Soldering thus became Taylor’s primary concern. If workers were deliberately reducing the pace at which they worked, whether it be due to a natural tendency to take it easy or various incentives, how could we create the conditions for them to work at maximum efficiency?

Taylor believed that management’s primary objective should be to secure what he called maximum prosperity for both the employer and the employee.

He advocated that to achieve any long-term success, the employer and employees needed to have a mutually beneficial relationship instead of viewing one another as adversaries.

💥🎁 New Year & Easter Deals On Amazon !

Don't miss out on the best discounts and top-rated products available right now!

🛒 Shop Now and Save Big Today!*As an Amazon Associate, I earn from qualifying purchases.

To accomplish this, Taylor supported that management should assume more of the responsibilities left for the workers.

During this time, workers develop their skills through observing another, a more seasoned worker, and perfecting their trade.

As a result, the workers themselves were far more knowledgeable in their work than management. So management allowed workers to determine how best to perform the individual tasks required to complete their assignments.

The problem with this, it’s hundreds of different possible ways of performing specific jobs emerged, so there wasn’t consistency between them. Workers had their self-styled ways of doing things that they would pass around.

Some Management concepts that Taylorism captures includes;

Division of Labor

Division of labor is a practice that Taylor believed in and wanted to divide work processed into very small, simple, and separate steps.

It meant instead of doing the whole project where you did it from beginning to end, you would only do one or two little steps, and then the next task was performed by the next person.

Taylor wanted to determine the best way, a standard, to do every part and every task to boost productivity.

Hierarchy

💥🎁 New Year & Easter Deals On Amazon !

Don't miss out on the best discounts and top-rated products available right now!

🛒 Shop Now and Save Big Today!*As an Amazon Associate, I earn from qualifying purchases.

Taylor also believed in the hierarchy and a clear chain of command that separated all the employees at the bottom of the organization from all the managerial people toward the top.

He wanted to do this so that the managers can design the work process and enforce how it was performed. Employees, as a result, would just follow directions. They just became doers, and the managers were then the thinkers.

Selection, Training and compensation

Taylor believed in selection and training, and compensation in a way that was a little different at the time.

Taylor wanted to select and train high performing workers or what he called first-class employees (First Class Workers) and then match them to a job that was best suited for them. He saw this as the ideal, and he believed that the most productive workers should be paid more.

He thought, on average, that most employees were not very hard workers, and he didn’t have a very high opinion of employees, and he wanted to get rid of those people, and if they couldn’t meet the higher standard, he would fire them and only the right people would be left.

Method: Time and Motion Studies.

Taylor’s method was called Time and Motion Studies. That meant he wanted to figure out the least amount of time on average, and it took to perform each task and even each part of each task. He really broke it down.

What were the fewest number of motions required for each small task? He wanted employees to work like they were machines.

Taylor shovels experiments

Taylor shovel experiments were a great example of a time and motion study.

💥🎁 New Year & Easter Deals On Amazon !

Don't miss out on the best discounts and top-rated products available right now!

🛒 Shop Now and Save Big Today!*As an Amazon Associate, I earn from qualifying purchases.

Working as a foreman for Bethlehem Steel Works in the 1900s, Taylor observed how workers could do more with less time. He analyzed coal shoveling at the factory and noticed that several workers brought different sizes of shovels from home.

He noticed that workers who brought small shovels could do more, but it took them longer, and workers who brought big shovels could do less, but it was faster.

It also meant that you could take fewer trips, so if you’re using a tiny shovel, you’d have to use more motions, more trips to the pile. He figured out the ideal amount of time and motion for shoveling.

He did an experiment to identify the ideal and that the best size shovel was one weighing about twenty pounds. As a result, he directed the organization to provide all the workers with the same size shovel. He also provided pay incentives for workers who could shovel more coal.

By making these changes, the organization dramatically increased its production.

Principles of Scientific Management By Frederick Taylor

They develop a science for each element of a man’s work, which replaces the old.

Taylor argued that a single and unified set of rules and procedures should be developed to outline how specific tasks should be performed.

This determination would be made based upon observing workers identify inefficiencies and track the amount of time it took for workers to complete specific tasks.

Once enough data was collected, management can establish a clear set of rules to help workers accomplish their tasks in the most efficient manner.

Scientifically select and then train, teach, and develop the workman.

Once these rules were created, management was responsible for training and developing workers under these procedures.

Unfortunately, training was lacking under the traditional model of management at this time. The original view was that since workers had more skills than management in terms of performing the work, they should be the ones to decide how it was to be performed.

💥🎁 New Year & Easter Deals On Amazon !

Don't miss out on the best discounts and top-rated products available right now!

🛒 Shop Now and Save Big Today!*As an Amazon Associate, I earn from qualifying purchases.

But Taylor believed that managers didn’t need to be the experts to identify preferred methods of operation.

By training workers, management can thus ensure that the tasks are being performed most efficiently.

Management could also reassign workers at this stage as the goal was to allow workers to perform the tasks they could excel in.

Management to cooperate with workers to ensure the work is being performed consistently

The third principle of scientific management was for management to cooperate with workers to ensure the work is being performed consistent with the previously identified rules. This ran contrary to popular opinion of management and workers viewing themselves as adversaries.

However, Taylor argued that both parties could achieve their desired outcomes, meaning lower costs for management and higher wages for workers if they worked in a mutually beneficial way.

Division of the work and the responsibility between the management and the workmen

The last component of scientific management is the equal division of labor between management and workers. Historically, workers were responsible for determining how the work should be performed.

But Taylor thought that this was rather unscientific, especially considering the individuals who worked in these types of jobs were, as Taylor put of low intelligence management, in a far better position to determine the optimal method of performing tasks.

Furthermore, workers needed to focus on what they do best, actually performing the tasks, and it was inefficient to have them do anything else.

Henry Ford and Frederick Taylor; The Assembly Line

Henry Ford took Taylor’s principles of efficiency to the next level was Henry Ford. In December of 1913, Henry Ford installs the first moving assembly line for an entire automobile factory’s mass production.

His innovation reduced the time it took to build a car from more than 12 hours to one hour and 33 minutes. … The most significant piece of Ford’s efficiency crusade was the assembly line.

💥🎁 New Year & Easter Deals On Amazon !

Don't miss out on the best discounts and top-rated products available right now!

🛒 Shop Now and Save Big Today!*As an Amazon Associate, I earn from qualifying purchases.

Boeing recently changed over the way they made their 737. They used to make it in one place like they initially did with the cars, and then they moved it into a more assembly-line style, which they call a lean production.

This is where the plane rolls along with all the tools and even the workers inside, just a few feet an hour until it’s done, and from start to finish, they were able almost to triple their production rate.

That’s a lot of savings for the company and a lot of savings for the client.

Scientific Management Example Today

If you go into just about any fast-food restaurant, especially the franchises, you’re going to see that they have figured out a rapid method, the one best way to make almost every single product they make.

If you’re making one burger versus two burgers, for example, you don’t make it the same way. You have to increase your productivity.

Advantages and disadvantages/Criticisms of Frederick Taylor Principles of Scientific Management

Advantages of Frederick Taylor Principles of Scientific Management

- He helps people boost productivity by 200 even 400% more in some cases, so that’s a big win.

- More work accomplished with fewer people, make more profit for the companies in a more consistent product of arguably higher quality. So let’s say if you break something on your car, you could get an exact duplicate that fits in perfectly. You don’t have to have a handmade piece, which would be incredibly expensive and not necessarily higher quality.

Disadvantages of Frederick Taylor Principles of Scientific Management

- Although Frederick Taylor’s scientific management has been criticized for its harsh and maybe even demeaning view of the worker, its focus on inefficiency through labor division, determining the optimal method of performing tasks, and incentivizing workers to perform a fair day’s work is still present today.

- Taylor’s work also created interest and worker productivity and ultimately led to many additional studies and subsequent theories.

- If you want to see the impact of Taylor’s work, just walk into any fast-food establishment, and you’ll surely see some of Taylor’s principles at work.

- Companies often failed to pay employees more. This is an essential part of Taylor’s advice. You have to pay people more because you want to hang on to the best people, and you want to keep them motivated, and he recommended they do this. Ford took that advice, and he paid people to double the going rate at the time, which is one of the critical reasons Ford had such great people and thrived. Most companies, however, did not do that.

- “Managers think employees do” philosophy that became common separated workers from the greater meaning of work. If they’re only tightening a bolt or painting a screw, they’re not connected to that broader satisfaction of making the whole product anymore.

- It deskilled employees and made them expendable. You could find and replace somebody in just a few moments. You didn’t have a lot of skill or time invested in each person.

- Survival the fittest philosophy took over. That harsh atmosphere resulted where it was a ruthless and unfeeling atmosphere.

- Employees’ burnout and dehumanization, being treated like a machine, and the mental anguish came with this mundane and repetitive work.